HSK-600 Polyvinylidene Difluoride (PVDF)

HSK-600

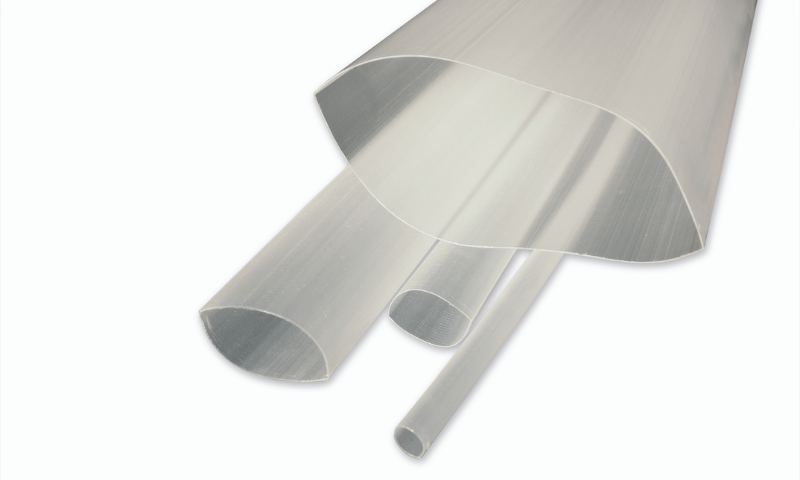

Cross-linked, translucent, semi-rigid, thin wall heat shrink tubing for high temperature applications. It has outstanding abrasion resistance and performs well in caustic environments. It is a highly flame retardant heat shrink tubing. Use this heat shrink tubing for automotive and military applications.

Standard Color: Translucent

Features

- 2:1 shrink ratio

- Transparent, thin wall, semi-rigid tubing

- Highly flame retardant

- Excellent dielectric properties

- Highly resistant to most industrial fuels, chemicals and solvents

- Outstanding abrasion, cut-through, high impact and high temperature resistance

- High degree of mechanical strength

- Meets UL, CSA and Military specifications

Uses

- Applications requiring high-temperature performance

- Electrical insulation and strain relief of high temperature wires, solder joints, terminals and connections

- Automotive wiring, fuse coverings

- Jacketing for resistors, capacitors and other components

- Military wire markers

Technical Specifications

Specifications

- UL VW-1

- CSA OFT

- AMS 3632

- SAE-AMS-DTL-23053/8

Technical Data

| Shrink Ratio | 2:1 |

|---|---|

| Minimum Recommended Shrink Temperature | 175°C (347°F) |

| Operating Temperature Range | -55°C to 175°C |

| Longitudinal Shrinkage | +1/-10% |

Physical / Electrical / Chemical Properties

| Tensile Strength | 5500 psi |

|---|---|

| Specific Gravity | 1.7 |

| Ultimate Elongation | 350% |

| Secant Modulus | (2%) 123,000 psi |

| Low Temperature Flexibility | 4 hrs. @ -55°C No cracking |

| Flammability | Self-extinguishing |

| Volume Resistivity | 1014 ohm-cm |

| Dielectric Strength | 900 vpm |

| Corrosion Resistance | Non-corrosive |

| Fuel, Oil, Solvent, Acids and Alkalis Resistance | Excellent |

| Expanded I.D. Minimum |

Recovered I.D. Maximum |

Recovered Wall Nominal |

Standard Packaging (per box) 4 Foot Lengths |

||||

|---|---|---|---|---|---|---|---|

| Size | in. | mm | in. | mm | in. | mm | Box Contents |

| 3/64 | .046 | 1.17 | .023 | 0.58 | .010 | 0.25 | 1,000′ |

| 1/16 | .063 | 1.60 | .031 | 0.79 | .010 | 0.25 | 1,000′ |

| 3/32 | .093 | 2.36 | .046 | 1.17 | .010 | 0.25 | 1,000′ |

| 1/8 | .125 | 3.18 | .062 | 1.57 | .010 | 0.25 | 1,000′ |

| 3/16 | .187 | 4.75 | .093 | 2.36 | .010 | 0.25 | 800′ |

| 1/4 | .250 | 6.35 | .125 | 3.18 | .012 | 0.30 | 500′ |

| 3/8 | .375 | 9.53 | .187 | 4.75 | .012 | 0.30 | 500′ |

| 1/2 | .500 | 12.70 | .250 | 6.35 | .012 | 0.30 | 400′ |

| 5/8 | .625 | 15.88 | .313 | 7.94 | .014 | 0.36 | 200′ |

| 3/4 | .750 | 19.05 | .375 | 9.53 | .017 | 0.43 | 200′ |

| 1 | 1.000 | 25.40 | .500 | 12.70 | .019 | 0.48 | 120′ |

| 11/2 | 1.500 | 38.10 | .750 | 19.05 | .020 | 0.51 | 96′ |

All information presented is believed to be reliable and is offered only as a guide to product selection. As each application is unique, Insultab can make no warranties as to the suitability of any products for a particular use. Specifications are subject to change.